Iyo kabhoni yemukati musimbi ndechimwe chezvinhu zvakakosha izvo zvinopesvedzera weldability yezvigadzirwa zvekugadzira. Simbi, musanganiswa wesimbi uye kabhoni, inogona kuve neakasiyana kabhoni yemukati mazinga, ayo anokanganisa zvakananga maitiro ayo emuchina, kusanganisira simba, kuoma, uye ductility. Kune ma welded forgings, kunzwisisa hukama pakati pekabhoni yemukati uye welding kuita kwakakosha kuti uve nechokwadi chekutendeseka uye mhando yemajoini akaiswa.

Masimbi akadzika-kabhoni, anowanzo aine isingasviki 0.30% kabhoni, ndiwo anonyanya kugadzirwa zvinhu. Aya masimbi anoratidza yakanaka ductility uye malleability, zvichiita kuti ive yakakodzera kune dzakasiyana siyana dzewelding application. Iyo yakaderera kabhoni yemukati inoderedza njodzi yekutsemuka munzvimbo yakakanganiswa nekupisa (HAZ) panguva uye mushure mekugadzira. Izvi zvinodaro nekuti yakaderera kabhoni mazinga anokonzeresa kuomarara, zvichireva kuti zvinhu zvacho hazvigone kuumba brittle microstructures senge martensite, izvo zvinogona kunetsa munzvimbo dzakasungwa. Nekudaro, mafogi ane yakaderera kabhoni zvemukati anowanzo kuve neashoma nyaya dzine chekuita nekutsemuka kana kukanganisa panguva yewelding maitiro.

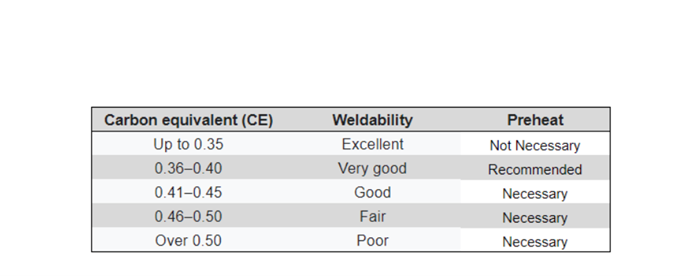

Mukupesana, sezvo kabhoni yemukati inowedzera, weldability yesimbi inoderera. Masimbi epakati-kabhoni, ane kabhoni ari pakati pe0.30% ne0.60%, anopa simba repamusoro uye kuomarara kana zvichienzaniswa nesimbi-kabhoni simbi asi zvinouya nenjodzi dzakawedzera panguva yewelding. Yakakwira kabhoni yemukati inotungamira mukuoma kukuru, izvo zvinowedzera mukana wekugadzira martensitic zvimiro muHAZ. Aya ma microstructures akaoma uye anowedzera brittle, achisimudza mikana yekutsemuka, kunyanya pasi pekunetseka kana kukanganisa. Kutarisirwa kwakakosha, senge preheating uye post-weld kupisa kurapwa, kunowanzodiwa kana welding yepakati-kabhoni simbi forgings kudzivirira nyaya idzi.

Masimbi epamusoro-kabhoni, ane anopfuura 0.60% kabhoni, anokonzeresa matambudziko makuru ekunama. Iyo yakakwira kabhoni yemukati inowedzera kuoma kwesimbi uye brittleness, zvichiita kuti iwedzere kutsemuka panguva yewelding process. Mune zvimwe zviitiko, masimbi epamusoro-kabhoni anogona kuda hunyanzvi hwekushongedza simbi kana kuti dzingave dzisina kukodzera kushivirira zvachose pasina gadziridzo dzakakura pakuita. Preheating, interpass tembiricha yekudzora, uye post-weld kupisa kurapwa kwakakosha kuti udzivise brittle kutadza mune yakakwirira-kabhoni simbi forgings.

Muchidimbu, iyo kabhoni yemukati yesimbi inoita basa rakakosha mukuona budiriro yewelding muzvikamu zvakaumbwa. Masimbi epasi-kabhoni ndiwo anokwenenzverwa zvikuru, nepo simbi dzepakati nepamusoro-kabhoni dzinoda kungwarira kudzora maparamendi ewelding kudzivirira hurema hwakadai sekutsemuka. Kunzwisisa iyo kabhoni yemukati uye kusarudza akakodzera welding maitiro kwakakosha kuti uve nechokwadi chekusimba uye kuita kwewelded forgings mune akasiyana maindasitiri ekushandisa.

Nguva yekutumira: Oct-16-2024